The invention has been transferred to the national phase - 50 countries

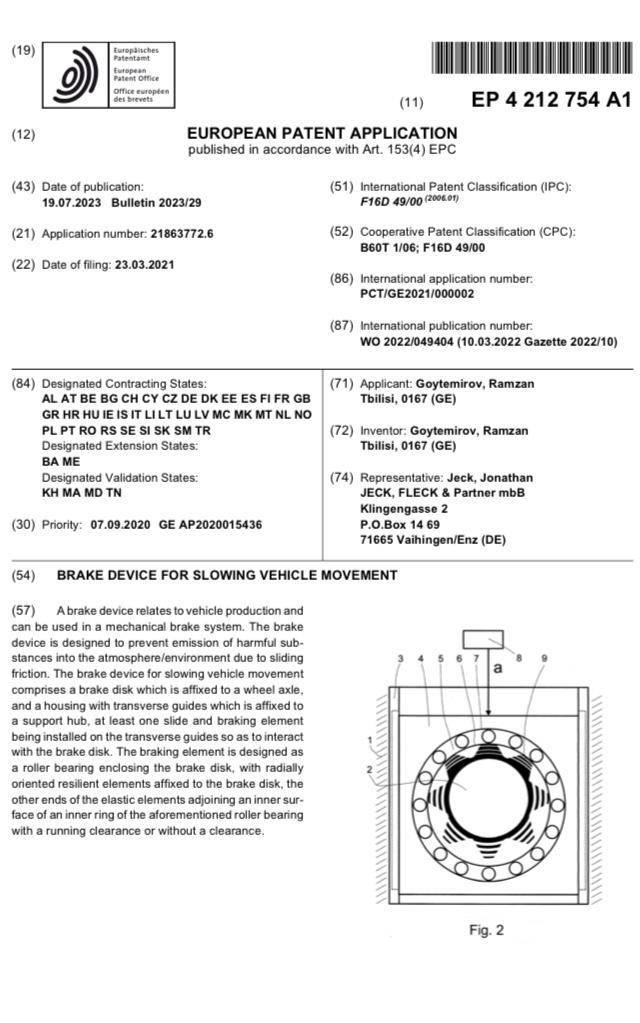

— A «Braking Device for slowing down the vehicle» has been developed and equipped. — Utility Model Patent (valid for 10 years): No. 20 2021 104 838, issued on 09/22/2021 by the German Patent and Trademark Office. — Patent for an invention (valid for 20 years) No. R 2021 7315 B, issued on 01.11.2021 by the Georgian Patent and Trademark Office.

— EAPO Patent No. 046347 (8 countries, valid for 20 years)

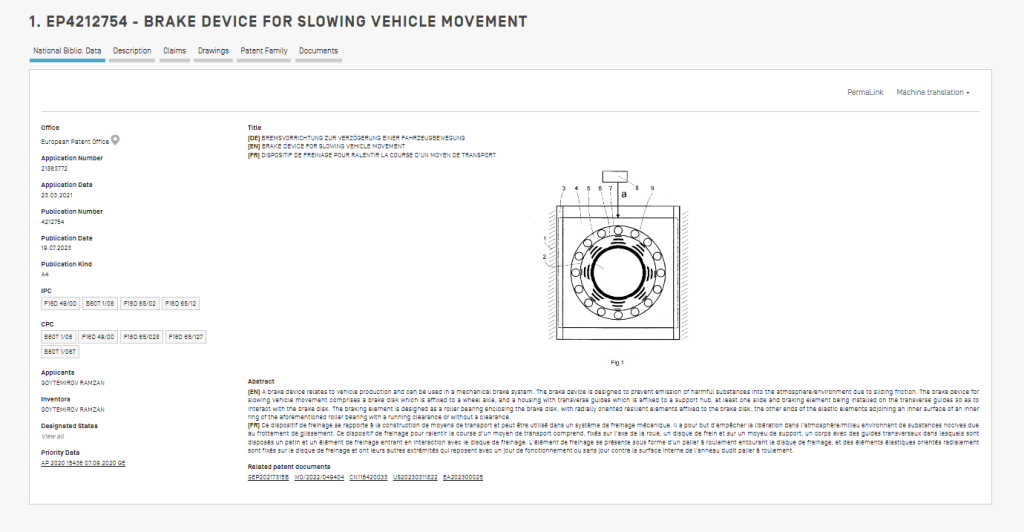

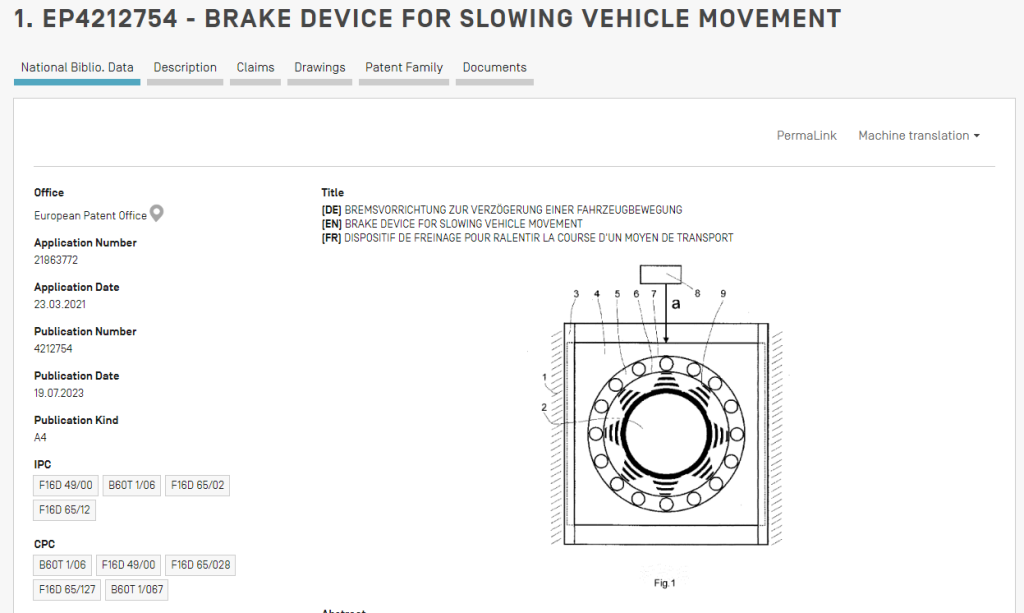

— Conclusion PCTGE2021000002. A positive conclusion of the examination of the international searching authority on: «novelty», «inventive step» and industrial applicability.

— the application was published by WO2022049404,

— The application is registered in EP 4 212 754 A1 — 39 countries, EAPO (8 countries), USA, China and India. There are 50 countries in total. – A positive conclusion has been issued by the National Academy of Sciences of Georgia. — Research work has been carried out, Models have been developed; the design of the device has been developed; special design work has been carried out; testing of components and parts of the device has been carried out; three tests have been conducted with testing of Models, a pilot prototype and an industrial experimental sample with four nodes of the braking device mechanism and with one traditional braking mechanism for accurate comparison, in identical conditions. Its viability, efficiency, environmental friendliness, safety, the possibility of sealing the device and its operation in oil have been proven… Brake devices have been manufactured and tested: Model; Prototype and Prototype – in the appendix, the test CERTIFICATE of the prototype (factory).

The Advantages of our Braking Device

ADVANTAGES OF THE CLAIMED CHARACTERISTICS WHEN BRAKING AN ELECTRIC MOTOR

- 1. OUR BRAKING DEVICE CAN OPERATE IN DECELERATION MODE IN A WIDE RANGE OF SPEEDS AND PARKING BRAKE MODE.

2. WE HAVE NO EMISSIONS/EMISSION OF DUST/NOISE AND SQUEAK, AND THE SERVICE LIFE OF THE BRAKING DEVICE IS DESIGNED FOR MILLIONS OF KILOMETERS.

3. THE PROBLEM OF DURABILITY, RELIABILITY AND SAFETY HAS BEEN SOLVED.

4. THE BRAKE DISC IS NOT SUBJECT TO HEAT. THERE IS NO SIGNIFICANT HEATING OF THE DEVICE, WHICH NEGATIVELY AFFECTS ITS PARTS AND BRAKING EFFICIENCY.

5. WHEN SLOWING DOWN, THE DISC DOES NOT LOCK OR THE BRAKES JAM. THE ABC SYSTEM IS MISSING.

6. RAINY PAGODA, RESERVOIRS, HUMIDITY DO NOT NEGATIVELY AFFECT THE BRAKING PROCESS, ON THE CONTRARY, THE PRESENCE OF LIQUID IMPROVES ITS OPERATION. THE DEVICE CAN BE SEALED AND OPERATED IN OIL EFFICIENTLY, LONG-LASTING, WITHOUT A SINGLE SPECK OF DUST, SMOOTHLY AND WITHOUT NOISE.

7. UNIFORM BRAKING IS ACHIEVED ON ALL WHEELS AT THE SAME TIME. DISK LOCKING IS ONE OF THE NON-MODULATED PROCESSES WHEN, HOW THE DISK DECELERATION SHOULD BE REGULATED. THIS IS ACHIEVED BY US THROUGH THE USE OF OUR BRAKING DEVICE, WHICH ENSURES THE SAFETY OF THE ABOVE-MENTIONED VEHICLE.

8. THE OVERALL DIMENSIONS OF THE DEVICE ARE 1.5 — 2 TIMES SMALLER THAN THE DIMENSIONS OF A TRADITIONAL BRAKE MECHANISM, WHICH INCLUDES THE BRAKE DISC AND PADS ALONG WITH THE CALIPER. THE DIAMETER OF THE DISC, WHICH PERCEIVES THE RESISTANCE FORCE, IS 2-3 TIMES SMALLER.

9. IT IS POSSIBLE TO ADJUST THE DEGREE OF DECELERATION OF THE DISC IN A WIDE RANGE OF SPEEDS WITHOUT BLOCKING THE BRAKE DISC, WHICH ALLOWS YOU TO ADJUST THE PROCESS OF DECELERATION OF THE DISC, AS WELL AS AUTOMATE THE ENTIRE BRAKING PROCESS.

1. Durability due to the use of elastic elements and a rolling bearing instead of rubbing parts, with the possibility of using lubrication;

2. Reliability due to the absence of overheating and cracking;

4. Ensuring the smooth operation of the mechanisms, due to the possibility of controlling the mechanism in high-speed operation mode, as well as when the load / tension of the bearing parts of the mechanism;

5. Ensuring high accuracy of controlled deceleration of the speed of the rotating shaft, without traditional precision settings of brake discs, for example, with a probe, which regularly have to be carried out during electromagnetic braking;

6. Ensuring a measured / moderate use of the force applied to the brake body, due to the possibility of regulating the elastic force of the elements slowing down the speed of the rotating shaft of the electric motor;

7. Ensuring high maneuverability of machine parts, machinery, machine tools, in particular, the sleeves of the CNC machine, due to the set of characteristics given in paragraphs 1-6;

8. Convenience and ease of operation, due to incomparably long repair periods;

9. Convenience and ease of maintenance, due to the absence of precision settings of the elements of the braking device of the electric motor;

10. Ensuring the safety and comfort of the user is due to the possibility of controlled